|

|

|

Ramie is

one of the strongest natural fibers. It exhibits even greater

strength when wet. Ramie fiber is known especially for its

ability to hold shape, reduce wrinkling, and introduce a silky

lustre to the fabric appearance. It is not as durable as other

fibers, and so is usually used as a blend with other fibers such

as cotton or wool. It is similar to flax in absorbency, density

and microscopic appearance. However it will not dye as well as

cotton. Because of its high molecular crystallinity, ramie is

stiff and brittle and will break if folded repeatedly in the

same place; it lacks resiliency and is low in elasticity and

elongation potential.[3]

|

|

|

|

Physical

and chemical properties of ramie fiber |

|

Cellulose

(wt%) |

Lignin

(wt%) |

Hemicellulose (wt%) |

Pectin

(wt%) |

Wax (wt%) |

Microfibrillar angle (°) |

Moisture

content (wt%) |

Density

(mg/m3) |

|

68.6 - 76.2 |

0.6 - 0.7 |

13.1 - 16.7 |

1.9 |

0.3 |

7.5 |

8.0 |

1.50 |

|

Source: [4] |

|

|

|

|

Mechanical properties of untreated ramie fibers |

|

Fiber

diameter (mm) |

Fracture

load (N) |

Tensile

strength (MPa) |

Fracture

strain (%) |

|

0.034 |

0.467 |

560 |

0.025 |

|

Source: [5] |

|

|

|

|

Uses |

|

Despite its strength, ramie has had limited

acceptance for textile use. The fiber's extraction and cleaning

are expensive, chiefly because of the several steps—involving

scraping, pounding, heating, washing, or exposure to chemicals.

Some or all are needed to separate the raw fiber from the

adhesive gums or resins in which it is ensheathed. Spinning the

fiber is made difficult by its brittle quality and low

elasticity; and weaving is complicated by the hairy surface of

the yarn, resulting from lack of cohesion between the fibers.

The greater utilization of ramie depends upon the development of

improved processing methods.

Ramie is used to make such products as

industrial sewing thread, packing materials, fishing nets, and

filter cloths. It is also made into fabrics for household

furnishings (upholstery, canvas) and clothing, frequently in

blends with other textile fibers (for instance when used in

admixture with wool, shrinkage is reported to be greatly reduced

when compared with pure wool.) Shorter fibres and waste are used

in paper manufacture.

Ramie is also used as an ornamental plant in

eastern Asia.

Ramie (Boehmeria nivea), commonly known as China grass, white

ramie, green ramie and rhea, is one of the group referred to as

the bast fiber crops. It is a hardy perennial belonging to the

Urticaceae or Nettle family, which can be harvested up to 6

times a year. It produces a large number of unbranched stems

from underground rhizomes and has a crop life from 6 to 20

years. The bark contains gums and pectins causing the fibers to

be useable only after chemical treatment. |

|

|

The

true ramie or ‘China Grass' is also known as ‘white ramie' and

is the Chinese cultivated plant. It has large heart shaped,

crenate leaves covered on the underside with white hairs that

give it a silvery appearance. Boehmeria nivea var. tenacissima,

is known as ‘green ramie' or ‘rhea'. It is believed to have

originated in the Malay Peninsula. It has smaller leaves which

are green on the underside, and is better suited to tropical

climates.

|

|

Ramie is one of the oldest textile fibers. It was used in mummy

cloths in Egypt during the period 5000 - 3000 BC, and has been

grown in China for many centuries. The main producers of ramie

today are China, Brazil, Philippines, India, South Korea and

Thailand. Only a small percentage of the ramie produced is

available on the international market. Japan, Germany, France

and the UK are the main importers, the remaining supply is used

domestically (in the country in which it is produced).

Ramie fiber is very durable, is pure white in colour and has a

silky luster. It is reported to have a tensile strength eight

times that of cotton and seven times greater than silk. However,

other reports claim that the tensile strengths of cotton, flax,

hemp and ramie are similar. These discrepancies can be partly

attributed to the effects of source of supply, method of

processing, the test conditions, temperature and humidity, on

the fiber strength.

The

stems of ramie grow to a height of 1 - 2.5 meters. The most

suitable climate for ramie is one which is warm and humid, with

an annual rainfall of at least 1000 mm. Well established plants

can tolerate drought and frost, but grow better without. As

ramie productivity is high it can rapidly deplete the soil of

nutrients.

|

|

|

|

|

Properties |

|

Advantages of Ramie as a Fabric :

|

|

●

|

|

Resistant to bacteria, mildew, alkalis, rotting, light,

insect attack. |

|

●

|

|

Extremely absorbent and therefore comfortable to wear,

especially during warm weather. |

|

|

|

Has natural stain resisting ability with ease of stain/soil

removal similar to that of linen (and this is better than

cotton). |

|

●

|

|

Not harmed by mild acids. |

|

●

|

|

Dyes fairly easily. |

|

●

|

|

Good wet-fastness in laundering - though dark colors may

lose their vibrancy over repeated launderings. |

|

●

|

|

Increases in strength when wet. |

|

●

|

|

Withstands high water temperatures during laundering. |

|

●

|

|

Smooth lustrous appearance improves with washing. |

|

●

|

|

Keeps its shape and does not shrink. |

|

●

|

|

Can be bleached. |

|

|

|

|

|

Disadvantages of Ramie as a Fabric :

|

|

●

|

|

Low in elasticity. |

|

|

●

|

|

Low abrasion resistance. |

|

●

|

|

Wrinkles easily (but application of wrinkle-resistant

finishes or blending with synthetic fibers can reduce the

problem in woven fabrics). |

|

●

|

|

Stiff and brittle. |

|

●

|

|

The fiber is high cost which reduces its competitiveness

against other textile fibers - this high cost is due to high

labor requirement for production, harvesting and

decortication. |

|

●

|

|

There is a need to de-gum the fiber prior to processing. |

|

|

|

|

|

|

|

|

Applications |

|

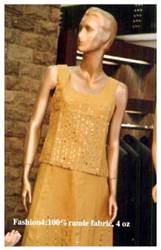

● |

|

Apparel. |

|

● |

|

dresses, suits, skirts, jackets, pants, blouses, shirts,

children wear, mixed with cotton in knitted sweaters. |

|

● |

|

Home Fashion. |

|

● |

|

curtains, draperies, upholstery, bedspreads, table linens,

sheets, dish towels. |

|

● |

|

Sewing thread. |

|

● |

|

Handkerchiefs. |

|

● |

|

Parachute fabrics. |

|

● |

|

Woven fire hoses. |

|

● |

|

Narrow weaving. |

|

● |

|

Canvas. |

|

● |

|

Filter cloth. |

|

● |

|

When used in a mixture with wool, shrinkage is reported to

be greatly reduced when compared with pure wool. |

|

● |

|

Short waste fibers are used for the production of high

quality papers, such as bank notes & cigarette papers. |

|

● |

|

As ramie takes up phosphorous, it is potentially useful for

cleaning up the Everglades. This region suffers from a

nutrient overload from the sugar industry. |

| |

|

|

|

|

Ramie

as a Blend |

|

|

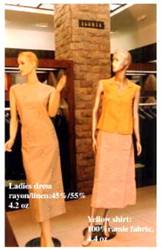

Ramie is most often blended (common is 55% ramie/45% cotton)

with other fibers for its unique strength and absorbency, luster

and dye-affinity. When blended with high-quality cotton it

offers increased luster, strength and color.

When mixed with

wool, ramie adds lightness and minimizes shrinkage. When blended

with rayon, it offsets the low wet strength.

|

| |

|

|

|

Care

Recommendations

for

Ramie

Fabrics |

| |

|

|

Care

procedures prescribed on the care labels of ramie products vary.

Items of 100 percent ramie should not require special care.

Generally, they may be laundered or dry-cleaned depending on

individual dyes, finishes and design applications.

High

temperatures will not harm the fiber itself, making washing in

hot water and ironing at high settings possible; however, color

retention, shrinkage control or properties of blended fibers may

dictate lower temperatures.

|

|

Recent laboratory testing done has

led to the conclusion that the best performance results when

gentler or more special handling is used in care. For example,

fabrics retained the best color and shape with the most

wrinkle-free appearance when they were dry-cleaned.

Machine washing in cold water on gentle cycle with line drying

was better than machine washing in warm water with tumble drying

on permanent press cool down cycle.

|

|

| |

|

|

|

|

Hand washing in cool water

with flat drying is the most strongly recommended home care

method for both knits and woven fabrics. The consumer who knows

the strengths and limitations of the fiber can receive maximum

service and enjoyment from ramie products.

When

storing ramie or ramie blends, lay them flat. Ramie fibers are

brittle and tend to break.

Avoid folding the garment or pressing

sharp creases in woven fabrics.

|

|

|

|

|

Ramie's

role in

farming

systems

: |

|

The following

characteristics

of the ramie

crop would

influence its

suitability in

Australian

farming systems:

|

|

● |

|

It is a

perennial

crop

with a

life of

6 to 20

years. |

|

● |

|

It is

capable

of

producing

high

yields

of

biomass

and if

the

harvesting

system

involves

total

removal

of this

biomass,

there

would be

a rapid

decline

in soil

fertility

and |

|

● |

|

Ramie is

subject

to a

number

of pests

and

diseases,

including

nematodes. |

|

|

|

|

Grades

|

|

● |

|

Fibers |

|

|

● |

|

Tow/Tops |

|

● |

|

Spun

yarns |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Processability |

|

The

crop

|

|

Ramie is a member of the Urticaceae or nettle family and is a

hardy perennial which produces a large number of unbranched

stems from underground rhizomes.

The stems of ramie grow to a

height of 1 to 2.5 m. The crop is generally propagated vegetatively, using rhizome or stem cuttings. Production begins

to decline once roots become overcrowded. |

|

|

|

|

|

|

Harvesting |

|

Ramie is normally harvested two to three times per year but

under good growing conditions can be harvested up to six times

per year. Harvesting is done just before or soon after the onset

of flowering, since there is a decline in plant growth at this

stage and maximum fiber content is achieved. Stems are harvested

by cutting just above the lateral roots or the stem can be bent,

to enable the core to be broken and the cortex can be stripped

from the plant in situ. Mechanical harvesters have been

developed but are not used commercially. After harvesting, stems

are decorticated while the plants are fresh as the bark gets

harder to remove as the plant dries out. The bark ribbons are

dried as quickly as possible to prevent attack by bacteria or

fungi.

The

dry weight of harvested stem from both tropical and temperate

crops ranges from about 3.4 to 4.5 t/ha/year; a 4.5 ton crop

yields about 1,600 kg/ha/year of dry non-de-gummed fiber. The

weight loss during de-gumming can be up to 25% giving a yield of

de-gummed fiber of about 1,200 kg/ha/year.

|

|

|

|

Extraction of fiber |

|

Extraction of the fiber occurs in three stages.

|

|

● |

|

Firstly, the cortex or bark is removed, either by hand or

machine, in a process called de-cortication. |

|

● |

|

The second stage involves scraping the cortex to remove most

of the outer bark, the parenchyma in the bast layer and some

of the gums and pectins. |

|

● |

|

The third stage involves washing, drying and de-gumming of

the residual cortex material to extract the spinnable fiber.

Details of the de-gumming processes tend to be regarded as

commercial-in-confidence information |

|

|

|

|

Ramie fiber |

|

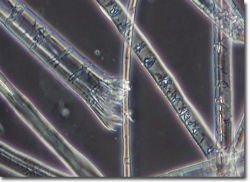

Ramie fiber is one of the premium vegetable fibers. The ultimate

fibers are exceptionally long and are claimed to be the longest

of vegetable origin, with one report claiming the fibers range

up to 580 mm, averaging about 125 mm.

Ramie fiber is very

durable, is pure white in colour and has a silky luster.

For

the hand spinner, ramie is treated similar to flax in that it

can be either wet or dry spun. A wet spun yarn will produce a

smooth softer yarn with high luster, while a dry spun yarn will

feel hairier, have less luster and a harsher handle. It can

readily be blended with other fibers such as wool or silk,

although the length of ramie can sometimes cause difficulties. |

|

|

|

|

|

|

|

|

Ramie spinning technology

|

|

|

|

|

|

Background

information |

|

History

|

|

Ramie is one of the oldest textile fibers. It was used in mummy

cloths in Egypt during the period 5000-3000 BC and has been

grown in China for many centuries. Brazil

began production in the late 1930s with production peaking in

1971 with about 30,000 t. Since then, production has steadily

declined as a result of competition with alternative crops, such

as soybeans and the importation of synthetic fibers. Production

in the Philippines began in the early 1950s, peaking in the mid

1960s with 5,500 t. Since then, production has declined

steadily.

|

|

|

|

Our

supplier partner

|

|

Hunan Isunte

|

|

Ramie

(Boehmeria nivea (L.) Gaud, is the only member of the Urticaceae

family used commercially for fiber production. The plant

produces a large number of erect and slender stems or stalks,

usually non-branching and grows from 4 to 7 leaves that are

silvery white underneath, 7.5 to 15 cm. long with clusters of

small greenish flowers, ranging from 8 to 16 mm in diameter. The

stalks turn brown and woody as they mature.

The fiber obtained from Ramie plant is one of the strongest

vegetable fiber known in the world today. It possesses highest

strength and length, good durability and absorbency with

excellent luster. These remarkable characters make it rather

more suitable for use in the manufacture of wide variety of

textiles and cordage products. However, despite its unique

quality, ramie has received comparatively less prominence in the

calendar of important crops of the world.

Recently

with the availability of more technical know how, the crop has

started getting slightly more importance and the countries like

China, Brazil and the Philippines have come forward with

commercial cultivation. |

|

|

|

Principal

Uses |

|

● |

|

Fabric

- Ramie tetoron |

|

● |

|

Yams |

|

● |

|

Industrial Threads |

|

● |

|

Sacks |

|

● |

|

Carpets |

|

● |

|

Twine

and Cordage |

|

|

|

|

|

|

Conditions

Required for Growing

|

|

Ramie

grows well in the areas having good rainfall and warm climate.

The following type of soil and climate is best suited for ramie

cultivation.

|

|

|

|

Soil

|

|

The soils

best suited for ramie are sandy loam or loamy, very sandy. The

clayey or gravel soil is not suitable. The plant is too much

sensitive to soil moisture conditions. It grows well in land,

which have adequate supply of moisture, well distributed

throughout the growing season. Soil must be well-drained i.e.

high land and should have no problem of water logging or

flooding. Flat and slopy lands are good. Ramie plants give poor

growth in the dry sandy soil and the poorly drained soils. The

soils deficient in calcium and poor in Base Exchange capacity

are also not suitable unless proper liming is done and

sufficient organic manure is added. The pH of the soils for

ramie should be around 5.5 to 5.6.

|

|

|

|

Climate

|

|

Ramie is

grown best in a warm moist climate where the temperature during

winters goes down to freezing. A temperature of approximately

25°C to 31°C during the summer and rainy months with annual

rainfall of 1500 to 3000 mm. evenly distributed throughout the

year is considered good for the growth of the crop. However, the

crop makes very little growth during winters. It is usually

grown at altitudes less than 300m above sea level. The ramie

plants are very much sensitive to frost. Even strong winds are

harmful as during storms the stalks rub with each other

resulting in breaking and ultimate lodging of the canes. The

relative humidity of 80% during the growing period is found to

be best.

|

|

|

|

Methods of

Cultivation

|

|

Ramie is

propagated vegetatively through rhizomes for commercial

production throughout the world. The cuttings of rhizomes are

planted directly in the field and the plants arising from them

spread rapidly. Rhizomes are obtained from the roots of healthy

and disease free plants which are dug out by a spade from an

already established plantation. The rhizomes are then removed

separately and cut into pieces of 10 to 15cm. in length.

These

pieces are planted in field immediately or may be stored in a

shady place for a week or so before planting. The practice of

propagation through rhizomes ensures good sprouting, clonal

purity and is economical. It makes the cultural operations also

simple. The quantity of rhizomes obtained from an unit area

depends on the age of plantation and variety. Usually the

quantity of rhizomes obtained from one hectare of 2 years old

plantation can give enough planting material to cover at least

20 hectares of land.

As a

perennial crop, ramie occupies the land for a number of years.

It is, therefore, necessary that the land is deeply and

thoroughly prepared. Planting should invariably be done under

good soil moisture condition. The planting period may extend

from May to September depending of course on the local seasonal

conditions. Rhizomes are planted 45 c.m. apart within the row

and 60 c.m. between two rows. About 250 to 275 kg. of rhizomes

are required for covering one hectare of land in a spacing of 60

cm x 45 cm.

Ramie can

also be cultivated in open blocks or as intercrop with coconut

plantations as is normally followed in the Philippines. Good

results have been obtained when sufficient quantity of organic

manure is applied in the field at the time of land preparation.

Lime if needed should be applied at the time of land preparation

itself at least 3 to 4 weeks before planting. The land is

leveled after proper laddering.

|

|

|

|

Methods of

Production

|

|

● |

|

Rhizome cuttings - 80-95% germination |

|

|

● |

|

Divisional of parent stock - 90% germination |

|

● |

|

Layering |

|

● |

|

Stem

cutting

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Planting

Season

|

|

Ramie can

be planted at the start of the rainy season, or anytime in

places where rainfall is evenly distributed throughout the year.

|

|

|

|

Distance

of Planting

|

|

Cuttings

are usually planted in furrows spaced 40 to 50 cm apart and 3 cm

deep at an angle of 45° leaving 1/3 or the length of the cutting

above the ground and 2/3 covered with pulverized soil. If

rhizome cuttings are used, they should be set in furrows about

3-4 cm deep, laid either flat or at an angle of 45°, from 30-40

cm apart in rows 80-100 cm between rows.

|

|

|

|

Rate of

Fertilization

|

|

If the

soil is rich, additional fertilizer of 80 kg N, 60 kg P2O and 60

kg K2O is recommended. If the soil is deficient such as sandy

loam soil, higher rates of nitrogen and potassium are needed.

Apply fertilizer using split method of application, spread out

from 5 to 8 times annually.

|

|

|

|

Some Major

Pests and Their Control

|

|

● |

|

Leaf

roller - causes heavy infestation resulting in complete

defoliation and cessation of the plant growth. |

|

● |

|

Ramie

weevil - brown beetle and green looper feed directly on

buds, leaves and petioles. Spray with Methyl Parathion. |

| |

|

Black

caterpillar - feeds directly on leaves thus leaving the

veins with a mesh-like appearance before falling. This can

be kept under control by spraying with organophosphorous

insecticides. |

| |

|

|

|

|

Some Major

Nematodes and Their Control

|

|

● |

|

Cotton-root-knot

nematode

- causes

root

galls.

Control

with

available

nematicides. |

| |

|

Bud

nomatodes, pin nomatodes - result to blighted tips of ramie

plants. Use available nematicides. |

|

|

|

|

Maturity

and Harvesting

|

|

Seventy

days after planting for the first harvest and ratooned 45-60

days for the succeeding harvests. Maximum of fiber yields are

attained on the second and third year. Rejuvenation of the area

is needed after 4-6 years.

|

|

|

|

Method of

Extraction

|

|

● |

|

Retting - extraction of fiber by means of soaking the stalks

in running water, pond, lake of designed tank. |

|

● |

|

Raspador-decorticator - a twoman raspador-decorticator could

produce 100 kgs of dried ramie fiber a day. |

|

|

|

|

Yield per

Hectare

|

|

Ramie has

an average yield of 1,575 kg of dry fiber based on three

cuttings per hectare per year. Approximate potential yield of

ramie per hectare (per year) may reach 2,700 to 4,800 kg of

fiber per year. Dry fiber recovery ranges from 3.5% to 5%.

|

|

|

|

Official

Standard Grades

|

|

Decorticated

|

|

● |

|

RD-A -

Special |

|

● |

|

RD-1 -

Good |

|

● |

|

RD-2 -

Fair |

|

● |

|

RD-3 -

Short |

|

● |

|

RD-O -

String |

|

● |

|

RD-T -

Tow |

|

● |

|

RD-W -

Waste |

|

|

|

|

Fermented

|

|

● |

|

RF-A -

Special |

|

|

● |

|

RD-1 -

Good |

|

● |

|

RD-2 -

Fair |

|

● |

|

RD-3 -

Short |

|

● |

|

RD-W -

Waste |

|

|

|

|

|

|

|

|

|

|

|

|

|