|

|

|

|

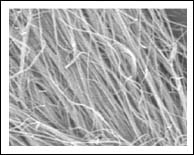

Tenbro

Bamboo fiber

and starchy

pulp are

made from

bamboo that

grows widely

throughout

China.

Starchy pulp

is a refined

product of

bamboo

through a

process of

hydrolysis-alkalization

and

multiphase

bleaching.

Chemical

fiber

factories

then process

it into

bamboo

fiber.

Repeated

technological

analysis has

proved that

TENBRO

bamboo fiber

has a

thinness

degree and

whiteness

degree close

to normal

finely-bleached

viscous and

has a strong

durability,

stability

and

tenacity. It

stands

abrasion and

possesses a

perfect

quality to

spin.

We have

developed

TENBRO

bamboo fiber

with

specifications

of

1.33dtex-.38mm-102mm

in length.

|

| |

|

|

Product

Name |

Specification |

|

TENBRO

Bamboo

Fiber |

1.33dtex×38mm |

|

1.56dtex×38mm |

|

1.67dtex×51mm |

|

2.22dtex×51mm |

|

3.33dtex×76mm |

|

3.33dtex×86mm |

|

5.56dtex×51mm |

|

| |

|

Physical

Parameters

of

Bamboo

Fiber |

|

Testing condition: Temperature : 20 ℃ Relative humidity: 65%±3%) |

1.4 X 38MM |

|

Dry tensile strength (CN/dtex) |

2.3 |

|

Dry elongation at break (%) |

23.5 |

|

Wet tensile strength (CN/dtex) |

1.33 |

|

Linear density percentage of deviation (%) |

0 |

|

Percentage of length deviation (%) |

-3.5 |

|

Over-length staple fiber (%) |

0.4 |

|

Over-cut fiber (mg/100g) |

3.2 |

|

Oil content (%) |

0.33 |

|

Residual sulfur (mg/100g) |

10.6 |

|

Whiteness (%) |

80 |

|

Coefficient of dry tenacity variation (CV)(%) |

12.65 |

|

Defect (mg/100g) |

6.1 |

|

Oil-stained fiber (mg/100g) |

0 |

|

Moisture regain (%) |

12.19 |

|

Rate |

Grade A |

|

|

|

|

|

|

|

|

Physical

Parameters

of

Bamboo

Charcoal

Fiber

|

|

|

|

Performance Index |

Bamboo Charcoal |

|

Linear Density (dtex) |

1.56Dtex *38mm |

|

Dry tensile strength (cN/dtex) |

2.01 |

|

Dry tensile strength difference coefficient (%) |

18.98 |

|

Elongation at break (dry) (%) |

18 |

|

Wet tensile strength (cN/dtex) |

1.07 |

|

Elongation at break (wet) (%) |

|

|

Wet modulus (cN/dtex/5%) |

|

|

Linear density deviation |

3.21 |

|

Fiber Length (mm) |

39.04 |

|

Length deviation rate (%) |

2.7 |

|

Ultra long textile fiber rate (%) |

0 |

|

Doubles the long textile fiber content (mg/100g) |

0 |

|

Finisher content |

|

|

Flaw content (mg/100g) |

3.8 |

|

Oil content (%) |

0.21 |

|

Residual sulfur (mg/100g) |

18.9 |

|

Moisture region (%) |

12.2 |

|

Whiteness (%) |

|

|

|

|

|

|

1.

Anti-bacterial

& Anti-odor

: |

|

Bamboo

Charcoal

contains

a

unique

agent

called

"bamboo

kun"

that

is

resistant

to

bacteria

(bamboo

grows

in

the

wild

without

any

pesticides)

This

is a

natural

property

without

adding

anti-bacterial

chemicals

that

may

cause

allergic

reactions.

Through

the

microscopic-sized

holes,

charcoals

will

absorb

harmful

matters

including

bad

smell

particles

simultaneously.

Bamboo

Charcoal

prevents

soiling

and

growth

of

odor

causing

bacteria

in

your

wetsuit

caused

by

body

oils,

sweat,

and

saltwater.

We

still

recommended

washing

your

wetsuit

after

every

use

to

prolong

the

lifespan

and

avoid

aging

the

neoprene. |

|

| |

|

2. Negative

oxygen ion

: |

|

Charcoal

generate

negative

oxygen ions.

Negative

oxygen ions

begin to

work in the

parasympathetic

nervous

system,

which

relaxes the

mind and

body. |

| |

|

3. Infrared

Ray : |

|

Due to its

porous

nature,

Bamboo

charcoal

absorbs far

infrared

light - the

so-called

"rays of

life" from

the

environment

and emits it

to the body.

Far infrared

is part of

the spectrum

of light

emanating

from the

sun. It is

not visible

to the eye,

but you fell

it as heat

penetrating

into your

skin. Far

infrared

warms your

body,

improves

blood

circulation

and speeds

up

metabolism

and cell

growth. |

| |

|

4. Natural : |

Bamboo

Charcoal is

eco-friendly

and

sustainable.

It is one of

the fastest

growing

plants which

re-grow

without

replanting. |

| |

|

5.

Comfortable

: |

Bamboo

Charcoal

feels silky

and

comfortable

against your

skin. |

| |

|

|

|

C. TENBRO LYOCELL

FIBER

|

|

Physical Parameters

of

Lyocell

Fiber

|

|

Performance

Index |

Lyocell

bamboo |

|

Linear

density

(dtex) |

1.56Dtex

*38mm |

|

Dry

tensile

stength

(cN/dtex) |

3.8 |

|

Dry

tensile

stength

different

coefficient(%) |

11.63 |

|

Elongation

at

break

(dry)

(%) |

15.8 |

|

Wet

tensile

stength

(cN/dtex) |

3.4 |

|

Elongation

at

break

(wet)

(%) |

16.9 |

|

Wet

modulus

(cN/dtex/5%) |

1.05 |

|

Linear

density

deviation |

-1.92 |

|

Fiber

length

(mm) |

37.9 |

|

Length

deviation

rate

(%) |

-0.26 |

|

Ultra

long

textile

fiber

rate

(%) |

0.7 |

|

Doubles

the

long

textile

fiber

content

(mg/100g) |

0 |

|

Finisher

content

(%) |

0.28 |

|

Flaw

content

(%)? |

0.25 |

|

Oil

content

(%)? |

0.25 |

|

Residual

sulfur

(mg/100g) |

7 |

|

Moisture

regain

(%) |

11.3 |

|

Whiteness

(%) |

55 |

|

|

|

|

|

Properties |

|

Lyocell

bamboo fiber

is Solvent

Humidity

Modulus

bamboo

fiber,during

which there

is no

chemical

reaction,

waste water

and gas, and

harmful

chemical

residues,

therefore it

is real

environmet-friendly

green fiber.

Lyocell

bamboo fiber

is not

viscose at

all and it

is the real

GREEN fiber

compared

with normal

bamboo

fiber..

Lyocell

Bamboo

boasts a

glazed

surface, a

smooth touch

feeling and

bright

gloss.

|

| |

| |

D. BAMBOO

MODAL FIBER

|

|

PHYSICAL

PARAMETERS

OF

BAMBOO

MODAL FIBER

|

|

Performance

Index |

Bamboo

modal

fiber |

|

Linear

Density

(dtex) |

1.33Dtex*38mm |

|

Dry

Tensile

strength

(cN/dtex) |

3.4 |

|

Dry

tensile

strength

difference

coefficient

(%) |

8.22 |

|

Elongation

at

break

(dry)

(%) |

13.9 |

|

Wet

tensile

strength

(cN/dtex) |

2.1 |

|

Elongation

at

break

(wet)

(%) |

|

|

Wet

modulus

(cN/dtex/5%) |

0.9 |

|

Linear

Density

deviation |

-0.75 |

|

Fiber

length

(mm) |

|

|

Length

deviation

rate

(%) |

-2.6 |

|

Ultra

long

textile

fiber

rate

(%) |

0.4 |

|

Doubles

the

long

textile

fiber

content

(mg/100g) |

2.3 |

|

Finisher

content

(%) |

|

|

Flaw

content

(mg/100g) |

0.9 |

|

Oil

content

(%) |

0.25 |

|

Residual

sulfur

(mg/100g) |

5.4 |

|

Moisture

regain

(%) |

10.33 |

|

Whiteness

(%) |

81 |

|

| |

|

|

|

Properties

bamboo modal fiber has much better wet strength than normal bamboo viscose bamboo fiber. And

hand feel of modal bamboo fiber is even better than normal viscose bamboo fiber.

|

| |

| |

E. TENBRO

BAMBOO MICRO

FIBER

|

|

|

PHYSICAL

PARAMETERS

OF

MICRO

BAMBOO FIBER

|

|

Performance

Index |

Bamboo

micro

fiber |

|

Linear

Density

(dtex) |

1.0D x 38mm |

|

Dry

Tensile

strength

(cN/dtex) |

2.18 |

|

Dry

tensile

strength

difference

coefficient

(%) |

12 |

|

Elongation

at

break

(dry)

(%) |

21.2 |

|

Wet

tensile

strength

(cN/dtex) |

1.22 |

|

Elongation

at

break

(wet)

(%) |

|

|

Wet

modulus

(cN/dtex/5%) |

|

|

Linear

Density

deviation |

2.3 |

|

Fiber

length

(mm) |

37.68 |

|

Length

deviation

rate

(%) |

-1.6 |

|

Ultra

long

textile

fiber

rate

(%) |

0.2 |

|

Doubles

the

long

textile

fiber

content

(mg/100g) |

3.2 |

|

Finisher

content

(%) |

0 |

|

Flaw

content

(mg/100g) |

7 |

|

Oil

content

(%) |

0.28 |

|

Residual

sulfur

(mg/100g) |

6.2 |

|

Moisture

regain

(%) |

11.42 |

|

Whiteness

(%) |

82 |

|

| |

|

|

|

Properties

Customers

can spin

yarn count

above 40ne

with micro

bamboo

fiber. It

will help to

improve the

strength and

evenness of

the yarn.

|

| |

| |

F. TENBRO

BAMBOO DOPE

DYED FIBER

|

|

|

|

Properties

Dope dyed bamboo fiber has good color fastness. We can have a wide range of

colorness according to customer requirements.

It will greatly reduce the cost for color yarn. |

| |

| |